Heating Equipment

The pig house heating diversity heating and local heating of two. Central heating by a central heating equipment heating and heat medium transport pipeline to the barn radiator, heating the air of pig, to maintain optimum temperature within the pig. Local heating hot water floor heating, electric panels, infrared lights. Such as heat lamp is employing the ion-tech to produce sun-like thermal radiation which can create ideal conditions for rearing pigs. In pig farming, the infrared transforms the electric into heat and heat radiation acts directly on the bodies of piglets, the blood and lymph vessels microcirculation is improved and a greater amount of oxygenated blood is supplied to the cells and reducing the heat waste to help piglets growth and resistance to infection and diseases.

Ventilation Equipment

The farms use ventilators multi large-diameter, low-speed, low-power fan. This large amount of fan ventilation, low noise, low power consumption, and durable.

The ventilation should pay attention to the following questions: (1) Avoid the fan ventilation short circuit, must not the fan set on the wall, below through the door to allow the air to form a short circuit; (2) unilateral exhaust should The side adjacent barn air vents located on the opposite side to avoid a discharge of the aggregate of inhalation is another pig immediately; (3) as far as possible so that the airflow in the most of the space in the barn, especially gutters on, do not result in dead ends, so as to achieve the purpose of ventilation.

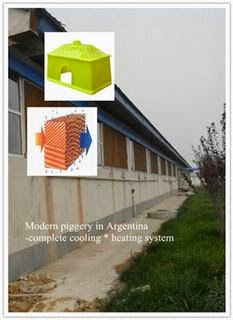

Cooling Equipment

Although ventilation is an effective cooling means, but only make down to close to homes outside ambient temperature when homes outside ambient temperature is greater than the upper limit of the pig production temperature (27 ~ 30 ℃), ventilation while cooling measures should also be taken to ensure The control suitable range.

Now farms commonly used cooling system such as – fan cooling system, spray cooling, spray cooling system and drip cooling system, humidity latter three cooling systems, is not suitable for farrowing homes. fan cooling system included fiber reinforced plastic fan,negative pressure fan for piggery,evaporation air cooler,evaporation cooling pad. Evaporation air cooler system is a kind of water-cooled air conditioner, integrating the functions of cooling, ventilating, dust preventing and smell removing. Because evaporation cooling efficiency can reach 75 to 90%, it has been gradually used widely around the world.

Amisy pig farming equipment has a full selection of pig equipment designed for piglets breeding, sow farrowing, fattening pigs breeding and adult pigs breeding. Hot sale products are pig farrowing crate, sow gestation crate, piglets nursery crate, pig feeders and waterer. Besides we also supply piggery cooling & ventilation machines, piggery warming machines, etc.

Email:nicholepandora@gmail.com or info@pig-farming.net

.jpg)

.jpg)